Material 3C90 and 3F3 are both commonly available, and when looking at their material specifications, we’ve decided to go with 3F3 as it performs better. We’ve targeted a core type called E38/8/25 (made by Ferroxcube), and we have investigated what materials it can be made from. However, I’ve not included it because both materials are pretty close, and it doesn’t influence the decision to go for 3F3 material. Not shown is another comparison that should be made, and that is the core saturation levels.

Over a typical operating range of 0 ☌ to 100 ☌, the 3F3 material would be the preferred choice. The next comparison shows how much the magnetic permeability changes with core temperature: The dotted lines indicate the core material losses, and at 1 MHz, the 3F3 material is a little superior to 3C90. But there isn’t a big difference between the two at 100 kHz, and they both have reasonable performance up towards 1 MHz. Both are 2000 times better than air, and that is important. This tells us how much better than fresh air they are at (a) concentrating the magnetic flux and (b) constraining it. At 100 kHz, they both have a value of around 2000. The solid lines show the material’s magnetic permeability (the ferrite “feel-good” factor). The first comparison is the frequency response, i.e., how high a frequency is the ferrite material suitable for: The next thing is to look into both these material types to see if one might be preferred over the other. The common material types are 3C90 and 3F3. The E38/8/25 core can be bought in several different ferrite materials. Study and choose the ferrite material (stages 2 and 3) Hence, we have targeted a planar core-set. Another aim of this design is to keep the overall profile height as low as possible. On the right is how the core set and PCB will be constructed The copper PCB tracks will form the coil loops, and we may have to stack several small PCBs to get the right number of turns.

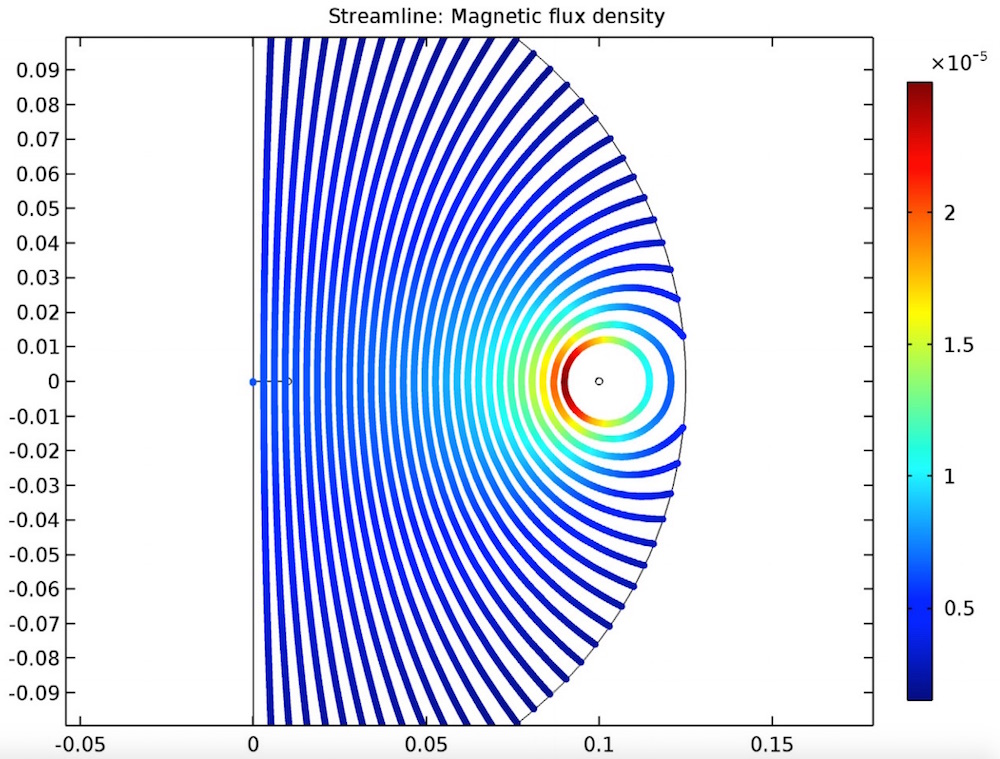

It is shown using the blue line in the figure below: It is the average travel distance of the magnetic flux when two core halves are brought together.

Highlighted in the red box is the core’s effective length (ℓ e) this is an important value for calculating the peak flux density.

#Flux density calculator full

The part number is E38/8/25, and two halves are needed to make a full core-set: The design we are using as the basis of this article is aiming for an inductance of about 1 mH, and the ferrite material that will be considered is a planar type made by Ferroxcube.

0 kommentar(er)

0 kommentar(er)